After my first shoddy attempt at a 40m HF dipole, I wanted to pivot into building a vertical for portable operations. Something with a lightweight mast that I could set up in a less ideal location.

Building the vertical

I purchased a 10m fibreglass squid pole and looked into guying strategies. Ultimately, it seemed the squid pole would be light enough that I could get away with wrapping velcro straps around an existing structure, or securing it to a metal stake with paracord if the wind speed wasn’t super high.

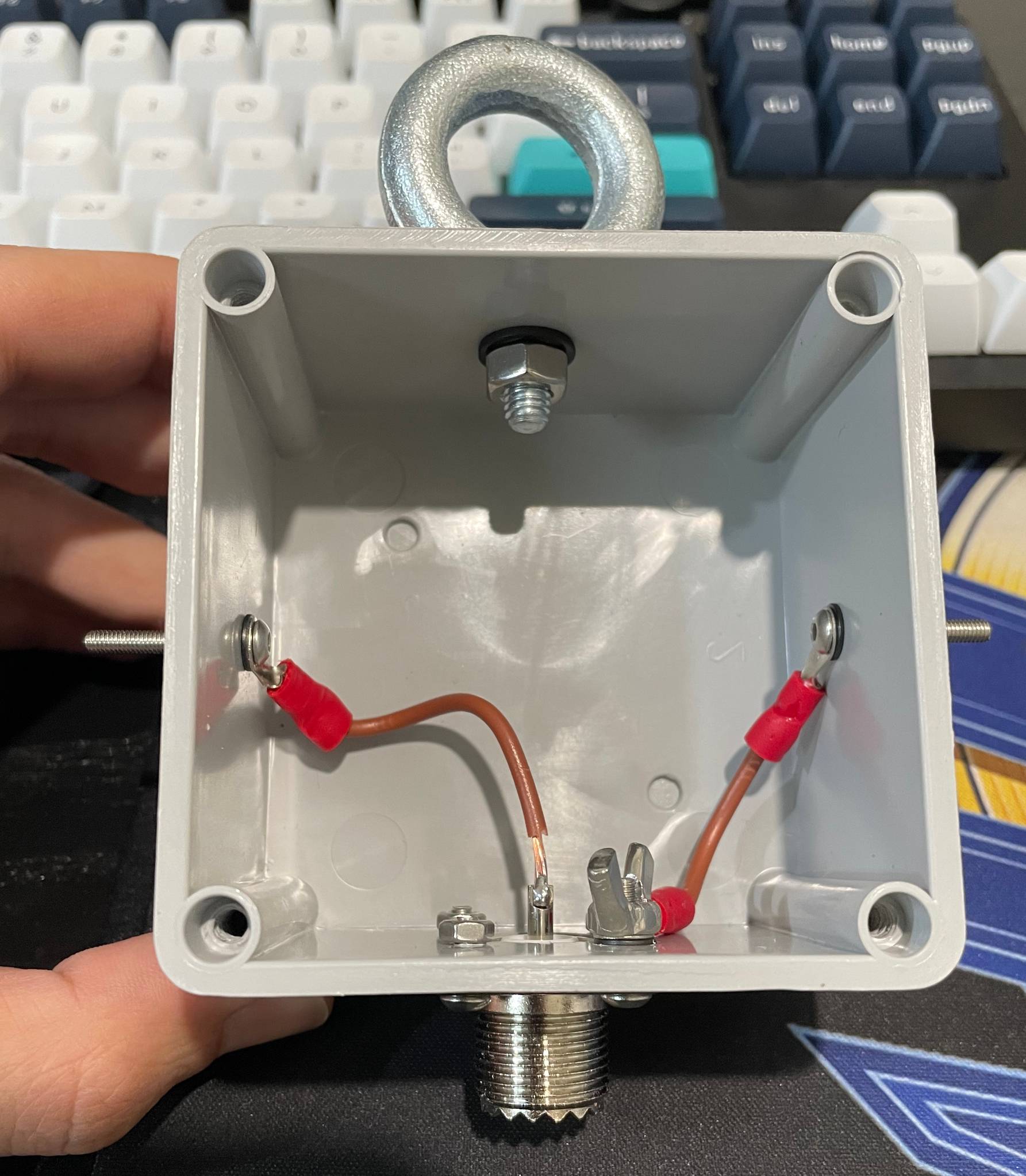

I used my existing antenna box for this and needed to re-solder the centre conductor wire again as the crappy connection broke. The second soldering attempt was stronger, but I was still iffy about whether this would hold.

Using a higher iron temperature while preheating the wire and conductor pin longer before applying solder made the difference for my 60/40 lead solder.

I decided to hold off on installing the toroid into this antenna box until I could give it more field testing and determine how much strain the solder joint could tolerate.

As I was delaying the balun build further, I used my existing ferrite as a rough coax choke at the radio-end of my feedline to prevent common mode current that causes interference. I wound 8 turns around the ferrite and secured it with zip ties.

After the bad decision of using enamelled copper wire for the dipole elements, I sourced a roll of flexible ~18AWG hookup wire which was much more suitable for the task. While this was being ordered and shipped, I went ahead with a first field test of the vertical using enamelled wire anyway, because apparently I’m a glutton for punishment.

I figured it that I had wire so I’d still get something out of it. I cut one ~10m wire for the driven element, and 5x 5m wires for the ground radials, all terminated with ring lugs.

First test run

I packed up and headed to my nearby field for the first test. The wind was roughly 20-25km/hr which I thought would be good for seeing how much wind load my squid pole’s mounting solution could handle.

Setup was easy when ignoring the crappy wire. The pole is secured to my metal stake with two lengths of paracord, and while I don’t need any fancy knots beyond my bastardised lashing knot to make it hold, I would want them in higher winds. Antenna wire is tied around the loop and folded back for tuning at a 3:1 ratio, then taped to the pole with masking tape.

I was hearing more signals than the compromised dipole setup, and ended up making my first two HF contacts on 40 metres to VK2NN and VK3GSX. I heard a ZL station calling CQ but wasn’t getting out to them after a few tries.

VK2NN helped me with troubleshooting some RF interference - thanks Peter! This appeared to be the result of leaving the ferrite choke fully exposed to the grass/earth. The RFI resolved when I wrapped the choke in a towel and isolated it from the earth. I need to test this further and confirm if it’s legitimately the cause, and whether enclosing the choke in a separate removable box with connectors will resolve it.

Towards the end of my QSO with VK3GSX, I noticed signal reception dropped significantly but I was still able to complete it. As it turns out, that degradation was due to the top of my antenna wire coming loose and lodging itself into a nearby tree which I noticed during teardown. While I was inspecting the antenna every few minutes, I obviously got distracted operating the radio and didn’t notice this. Whoops.

Second test run

I received my new wire and went out a few days later for a second test after cutting the antenna wire and 6 radials.

I was amazed at how much easier it was to work with. I’m able to get a great tune every time with the foldback method as I can cut this wire much more accurately.

My antenna wire is cut to 10.3m, and I’ve marked two 15cm lengths back from the end. When tying my loop to the squid pole, I fold back between these two markings which nudges my tuned centre frequency slightly depending on if I want lower or higher ends of the band.

The enamelled wire has been banished to the bottom of the radio parts bin where it will think about it’s behaviour.

During the second test run I was able to make my first ZL contact with ZL2ACJ on 15 metres which was great compared to the performance of the old wire! I moved to a second location and heard several JA stations as sunset closed in, but I couldn’t make a contact with them.

Lessons learned

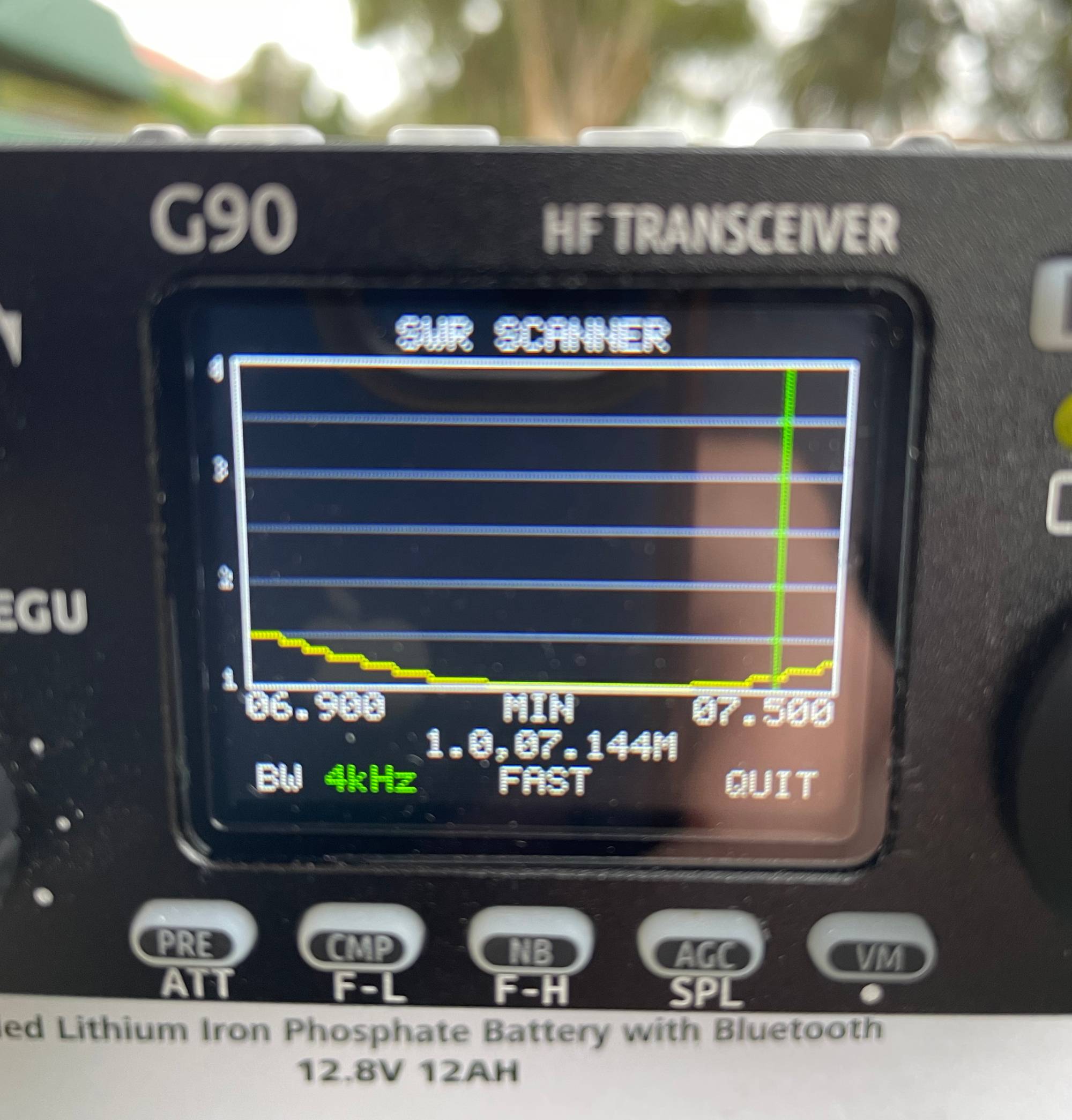

Overall I think the first runs of this antenna have been a great success and I can’t wait to keep experimenting with the vertical. My next plans are to run FT8 on the G90, and also taking the vertical down to a beach so I can use the salt water as part of my ground plane for more gain.

The experience of both antennas has definitely given me the bug for building them, and I’m excited to get back onto finishing the lightweight dipole for this squid pole setup. I am looking at buying a NanoVNA to get more accurate measurements than the G90 for future projects, as I’d love to compare these against the antenna modelling I’m learning with MMANA-GAL.

The G90 with stock mic has been producing a very clean audio signal while using the mic compression feature, however it’s been noted in very windy conditions that the mic captures some noise without a wind shield. I’ll need to look at a DIY shield for the stock mic.

The connection lugs in my antenna box need lock nuts added or else connecting/disconnecting antenna elements just untightens the nuts and twists on the cables.

It’s mainly a problem for the side soldered to the centre conductor, and this is my worry. It causes extra setup and teardown time, as I need to open up the box and re-tighten during connection and disconnection.

I hate the rough coax choke. It adds so much extra weight to the coax cable which causes it to tangle worse and twist beyond its designed limits. After all of the abuse I’ve given this cable due to the amount of untangling, I think that I now need to make a new cable as I’m getting signal problems in different alignments. I will definitely make a proper balun, or an enclosed & detachable coax choke which can be removed from the cable for future applications.

I need to practice some proper knots for my antenna rigging. Getting more comfortable with clove hitches for the lashing knot, and practicing some other knots for tensioning future dipole supports would be time well spent.